Flint Machine Tools is proud to be the exclusive partner and importer of TOS Varnsdorf Horizontal Boring Mills and Machining Centers for the United States of America. FMT found success as the Southeastern regional dealer prior to becoming the national importer in 2016. From the beginning we have committed to growing our service and support capabilities for this historic brand of boring mills by factory training service teams, building spare parts inventory stateside and working with exceptional full servicing dealers nationwide.

TOS Varnsdorf is a privately owned machine tool builder in Czech Republic with a rich history dating back to 1903. Quality, reliability and high technical levels have been a company tradition and main reason why TOS Varnsdorf celebrated 120 years of existence in 2023.

TOS PRODUCTS

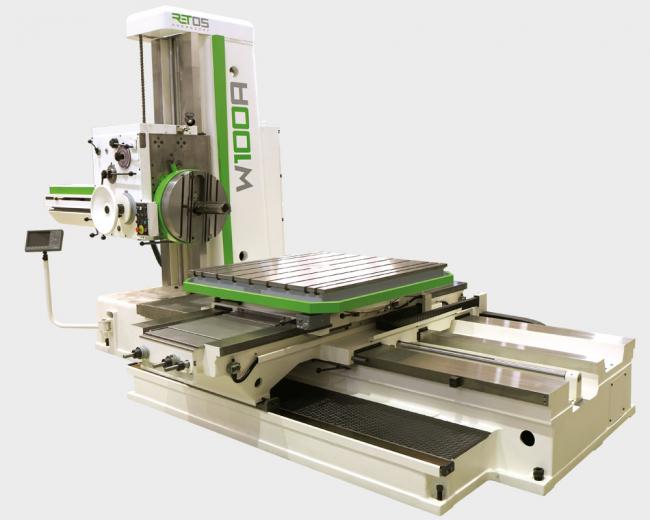

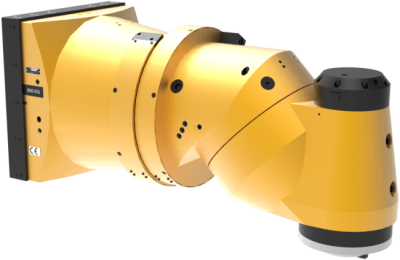

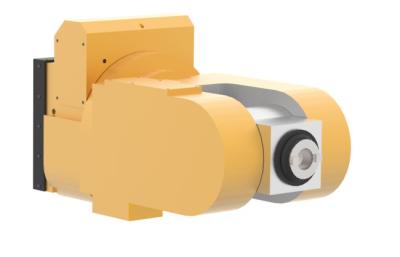

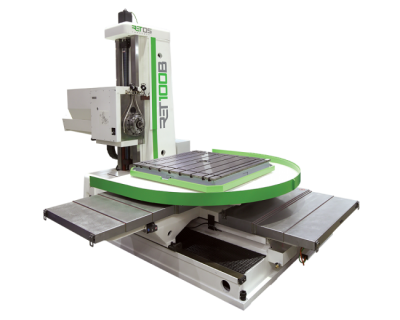

The legendary machines that have made TOS Varnsdorf famous all over the world started with the production of the WHN 13 in 1963. The versatile machine design offers a wide choice of parameters and optional accessories thus making them suitable for universal usage.

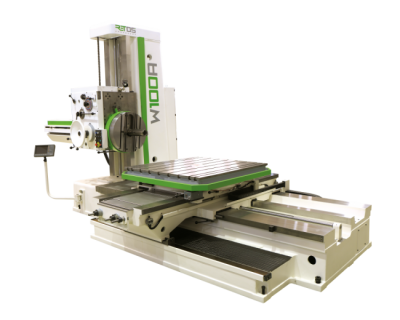

- Work Spindle Diameter: 100mm (3.93”)

- Spindle Speed Range 10-2,500 RPM

- X Travel-Table Traverse: 1,250mm (49”)

- Y Travel-Headstock Vertical Travel: 1,100mm (43”)

- Z Travel- Longitudinal Table Travel: 940mm (37”)

- W Travel-Spindle Stroke: 710mm (27.95”)

- Table Clamping Area: 1,000 x 1,120mm (39”x44”)

- Max Workpiece Weight: 3,000kg (6,613 lbs.)

- Optional Accessories: Angle Plates, Clamping Cubes, Milling Heads, Facing Heads, Automatic Tool Changers, Pickup Stations for Automatic Exchange of Special Accessories, Etc

- Work Spindle Diameter: 105mm (4.13")

- X Travel-Table Traverse: 1,800/2,000mm (70" / 78")

- Y Travel-Headstock Vertical Travel: 1,250mm/1,600mm (49"/63")

- Z Travel- Longitudinal Table Travel: 1,250mm (49")

- W Travel-Spindle Stroke: 630mm (24.8")

- Table Clamping Area: 1,400 x 1,400mm (55" x 55")/ 1,400x1,600mm (55" x 63")

- Max Workpiece Weight: 5,000/3,000kg (11,023/6,613 lbs.)

- Angle Plates, Clamping Cubes, Milling Heads, Facing Heads, Automatic Tool Changers, Pickup Stations for Automatic Exchange of Special Accessories, Etc

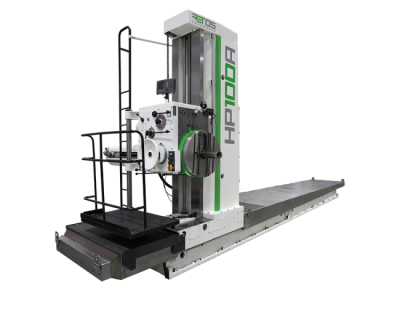

- Work Spindle Diameter: 112mm (4.40")

- Spindle Speed Range: 10-3,300 RPM

- X Travel-Table Traverse: 1,600 / 2,000mm / 2,500 / 3,000 (63" / 78" / 98" / 118")

- Y Travel-Headstock Vertical Travel: 1,250mm / 1,400 / 1,600mm (49" / 55" / 63")

- Z Travel- Longitudinal Column Travel: 800 / 1,000 / 1,250mm (31.5" / 39" / 49")

- W Travel-Spindle Stroke: 710mm (27.95")

- Table Clamping Area: 1,250 x 1,400mm / 1,400x1,600mm (55" x 63") / 1,400 x 1800 (55" x 70")

- Max Workpiece Weight: 5,000kg(11,023 lbs.)

- Pallet Changer, Angle Plates, Clamping Cubes, Milling Heads, Facing Heads, Automatic Tool Changers, Pickup Stations for Automatic Exchange of Special Accessories, Etc

- Work Spindle Diameter: 130 (5.11")

- Spindle Speed Range: 10-3,000 RPM

- X Travel-Table Traverse: 2,000 / 2,500 / 3,000 / 3,500 / 4,000mm (78" / 98" / 118" / 137 / 157")

- Y Travel-Headstock Vertical Travel: 1,600 / 2,000 / 2,500mm (63" / 78" / 98")

- Z Travel- Longitudinal Column Travel: 1,000 / 1,250 / 1,600 / 2,000mm (39" / 49" / 63" / 78")

- W Travel-Spindle Stroke: 800mm (31.5")

- Table Clamping Area: 1,600 x 1,800mm (63" x 70") / 1,800 x 2,240mm (70" x 88")

- Max Workpiece Weight: 12,000kg(26,455 lbs.)

- Pallet Changer, Angle Plates, Clamping Cubes, Milling Heads, Facing Heads, Automatic Tool Changers, Pickup Stations for Automatic Exchange of Special Accessories, Etc

- Work Spindle Diameter: 130mm (5.11") / 150mm (5.9")

- Spindle Speed Range: 10-3,000 RPM / (Optional 10-4,500 RPM on WHN 13)

- X Travel-Table Traverse: 3,500 / 4,000 / 5,000 / 6,000mm (137" / 157" 196" / 236")

- Y Travel-Headstock Vertical Travel: 2,000 / 2,500 / 3,000 / 3,500mm (78" / 98" / 118" / 137")

- Z Travel- Longitudinal Column Travel: 1,250 / 1,600 / 2,200 / 3,200mm (49" / 63" / 86" / 126")

- W Travel-Spindle Stroke: 800mm (31.5") / 900mm (35.4")

- Table Clamping Area: 1,800 x 1,800mm (70" x 70") / 1,800 x 2,220mm (70" x 86") / 1,800 x 2,500mm (70" x 98") / 2,000 x 3,000mm (78" x 118") / 2,500 x 3,000mm (98" x 118")

- Max Workpiece Weight: 12,000kg (26,455 lbs.) / 25,000kg (55,115 lbs.)

- Pallet Changer, Angle Plates, Clamping Cubes, Milling Heads, Facing Heads, Automatic Tool Changers, Pickup Stations for Automatic Exchange of Special Accessories, Etc

- Work Spindle Diameter: 130mm (5.11")

- RAM Size: 320 x 400mm (12.6" x 15.7")

- RAM Stroke V Travel: 700mm (27.6")

- Spindle Speed Range: 10-3,000 RPM

- X Travel-Table Traverse: 3,500 / 4,000 / 5,000 / 6,000mm (137" / 157" 196" / 236")

- Y Travel-Headstock Vertical Travel: 2,000 / 2,500 / 3,000mm (78" / 98" / 118")

- Z Travel- Longitudinal Column Travel: 1,250 / 1,600 / 2,200 / 3,200mm (49" / 63" / 86" / 126")

- W Travel-Spindle Stroke: 650mm (25.6")

- Table Clamping Area: 1,800 x 1,800mm (70" x 70") / 1,800 x 2,220mm (70" x 86") / 1,800 x 2,500mm (70" x 98") / 2,000 x 3,000mm (78" x 118") / 2,500 x 3,000mm (98" x 118")

- Max Workpiece Weight: 12,000kg (26,455 lbs.) / 25,000kg (55,115 lbs.)

- Pallet Changer, Angle Plates, Clamping Cubes, Milling Heads, Facing Heads, Automatic Tool Changers, Pickup Stations for Automatic Exchange of Special Accessories, Etc

- Work Spindle Diameter: 130mm (5.11") / 150mm (5.9") / 160mm (6.3")

- Spindle Speed Range: 10-3,000 RPM / 10-2,500 RPM(opt. 2,800) / 10-2,400 RPM

- RAM Size: 450 x 450mm (17.7 x 17.7")

- RAM Stroke V Travel: 1,200mm (47.2")

- X Travel-Table Traverse: 3,500 / 4,000 / 5,000 / 6,000mm* (137" / 157" 196" / 236")

- Y Travel-Headstock Vertical Travel: 2,000 – 6,000mm (98" – 236") in increments of 500mm

- Z Travel- Longitudinal Column Travel: 1,500 / 2,000 / 2,500mm (59" / 78" / 98")

- W Travel-Spindle Stroke: 700mm (27.6") / 800mm (31.5")

- Table Clamping Area: 2,000 x 2,000mm (78" x 78") / 2,500 x 2,500mm (78" x 98") / 3,000 x 3,000mm (118" x 118") / 3,000 x 3,500mm (118" x 137") / 3,000 x 4,000mm (118" x 157")

- Max Workpiece Weight: 30,000kg (66,138 lbs.) / 50,000kg (110,231 lbs.)

- Pallet Changer, Angle Plates, Clamping Cubes, Milling Heads, Facing Heads, Automatic Tool Changers, Pickup Stations for Automatic Exchange of Special Accessories, Etc

In 1995 the WPD floor-type milling and boring machine debuted at the International Industrial Fair Brno winning a gold medal for innovation. Since then the production series has expanded to include additional models and hundreds of units have been installed worldwide

- Work Spindle Diameter: 130mm (5.11")

- Spindle Speed Range: 10-3,000 RPM

- RAM Size: 320 x 400mm (12.6 x 15.7")

- RAM Stroke Z Travel: 700mm (27.6")

- X Travel-Column Traverse: 3,000- 20,000 (118" – 787") in 1,000mm increments

- Y Travel-Headstock Vertical Travel: 2,000 / 2,500 / 3,000mm (78" / 98" / 118")

- W Travel-Spindle Stroke: 650mm (25.6")

- Optional Accessories: Rotary Tables, Floor Plates, Angle Plates, Clamping Cubes, Milling Heads, Facing Heads, Automatic Tool Changers, Pickup Stations for Automatic Exchange of Special Accessories, Etc.

- Work Spindle Diameter: 130mm (5.11") / 150mm (5.9") / 160mm (6.3")

- Spindle Speed Range: WRD 130- 3,000 RPM / WRD 150- 2,500 RPM (Opt. 2,800 & 1,500) / WRD 160- 2,400 RPM

- RAM Size: 450 x 450mm (17.7 x 17.7")

- RAM Stroke Z Travel: 1,20mm (47.2")

- X Travel-Column Traverse: 5,000- 29,000 Plus (196" – 1,141) in 2,000mm increments

- Y Travel-Headstock Vertical Travel: 2,000 – 6,000mm (98" – 236") in increments of 500mm

- W Travel-Spindle Stroke: WRD 130 -700mm (27.6) / WRD 150- 800mm (31.5") / WRD 160-800mm (31.5")

- Optional Accessories: Rotary Tables, Floor Plates, Angle Plates, Clamping Cubes, Milling Heads, Facing Heads, Automatic Tool Changers, Pickup Stations for Automatic Exchange of Special Accessories, Etc.

- Work Spindle Diameter: 170mm (6.7") / 200mm (7.8")

- Spindle Speed Range: WRD 170- 2,200 RPM / WRD 200- 1,800 RPM

- RAM Size: 550 x 550mm (21.6 x 21.6")

- RAM Stroke Z Travel: 1,50mm (59")

- X Travel-Column Traverse: 5,000- 29,000 Plus (196" – 1,141") in 2,000mm increments

- Y Travel-Headstock Vertical Travel: 3,000 – 6,000mm (118" – 236") in increments of 500mm

- W Travel-Spindle Stroke: 1,00mm (39.3")

- Optional Accessories: Rotary Tables, Floor Plates, Angle Plates, Clamping Cubes, Milling Heads, Facing Heads, Automatic Tool Changers, Pickup Stations for Automatic Exchange of Special Accessories, Etc.

- Main Motor Speed: 5,000 RPM

- RAM Size: 500 x 500mm (19.6 x 19.6")

- RAM Stroke Z Travel: 1,50mm (59")

- X Travel-Column Traverse: 5,000- 25,000 (196" – 984") in 2,000mm increments

- Y Travel-Headstock Vertical Travel: 1,600 / 2,000 / 2,500 / 3,000mm (63" / 78" / 98" / 118")

- Optional Accessories: Rotary Tables, Floor Plates, Angle Plates, Clamping Cubes, Milling Heads, Facing Heads, Automatic Tool Changers, Pickup Stations for Automatic Exchange of Special Accessories, Etc.

- Work Spindle Diameter: 112 (4.4")

- Spindle Speed Range: 4,000 RPM / 6,000 rpm / 7,500* (no travelling spindle)

- X Travel-Table Traverse: 1,500 / 2,000 / 2,500 / 3,000mm (59" / 78" / 98" / 118")

- Y Travel-Headstock Vertical Travel: 1,250 / 1,600 / 2,000mm (49" / 63" / 78")

- Z Travel- Longitudinal Column Travel: 1,500 / 2,000 / 2,500mm (59" / 78" / 98")

- W Travel-Spindle Stroke: 650mm (25.6")

- Table Clamping Area: 1,250 x 1,250mm (49" x 49") / 1,250 x 1,600mm (49" x 63")

- Max Workpiece Weight: 6,000kg (13,227 lbs.)

- Turning Table: 1,600 Diameter (63"), 400 RPM

- Pallet Changer, Angle Plates, Clamping Cubes, Milling Heads, Facing Heads, Automatic Tool Changers, Pickup Stations for Automatic Exchange of Special Accessories, Etc

- Work Spindle Diameter: 130 (5.1")

- Spindle Speed Range: 4,000 RPM / 4,500 / 5,000 rpm / 7,500* (no travelling spindle)

- X Travel-Table Traverse: 2,000 / 3,000mm / 4,000 / 5,000 (78" / 118" / 157" / 196")

- Y Travel-Headstock Vertical Travel: 1,500 / 2 ,000 / 2,500mm / 3,000 (59" / 78" / 98" / 118")

- Z Travel- Longitudinal Column Travel: 1,500 / 2 ,000 / 2,500mm / 3,000 (59" / 78" / 98" / 118")

- W Travel-Spindle Stroke: 800mm (31.5")

- Table Clamping Area: 1,800 x 1,800mm (70" x 70") / 1,800 x 2,220mm (70" x 86") / 1,800 x 2,500mm (70" x 98") / 2,000 x 3,000mm (78" x 118") / 2,500 x 3,000mm (98" x 118")

- Max Workpiece Weight: 20,000kg (44,092 lbs.)

- Turning Table: 2,000 Diameter (78")/ Max Weight Capacity 10,000kg(22,046 lbs.) 250 RPM

- Pallet Changer, Angle Plates, Clamping Cubes, Milling Heads, Facing Heads, Automatic Tool Changers, Pickup Stations for Automatic Exchange of Special Accessories, Etc

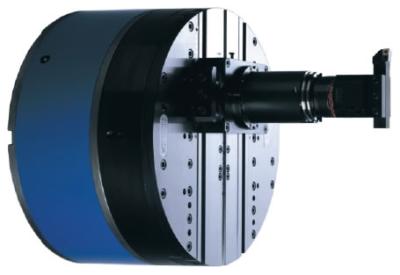

- Produced in house by TOS Varnsdorf: The additional rotary tables with horizontal adjustment (V axis travel) are designed for WRD series horizontal floor type boring machines and adaptable for machines by other manufacturers. They allow for interpolation in the longitudinal axis, in the rotational axis and both axes simultaneously. The positional accuracies can be programmed with increments of 0.001 degrees. The B axis coordinate is driven by a Master & Slave system, which incorporates two separate servo drives each with their dual pinion gear for zero backlash.

- 5,000 kg / 10,000 kg / 16,000 kg / 20,000 kg / 30,000 kg, 50,000kg, 80,000kg

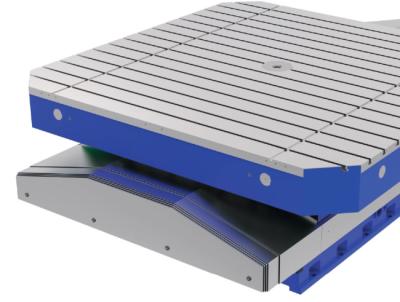

- The automatic pallet changer replaces the standard rotary table and significantly speeds up setup time and allows the spindle to continue machining increasing productivity. Designed for WHN 110/130, WHN 13/15, WHR 13, Maxima I/II and the WHT 110/130 machines.

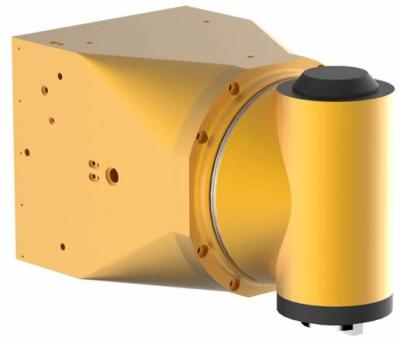

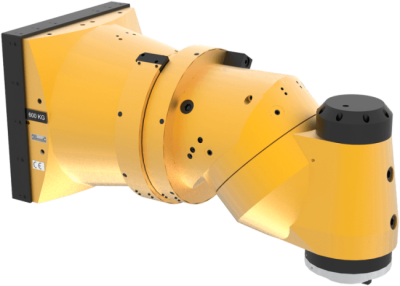

- Several styles of tool changers are produced in house including chain magazines, meandering magazines, rack magazine and robotic tool changers. It is possible to equip the tool changer with a tilting manipulator allowing you to load tools vertically directly into mounted milling heads.

RETOS PRODUCTS