The floor-type boring machines are characterized by a modern technical design of the structure and high level of performance. They can be supplemented with a number of technological devices, which can greatly extend the technological capabilities of the machine.

The machines are intended for precision and high-efficient coordinate boring, drilling, milling and thread-cutting particularly in the case of large-scale, heavy and structurally difficult work-pieces made of cast iron, cast steel and steel.

According to concrete process needs, the machines can be extended with a clamping field consisting of clamping plates or with one of more additional tables.

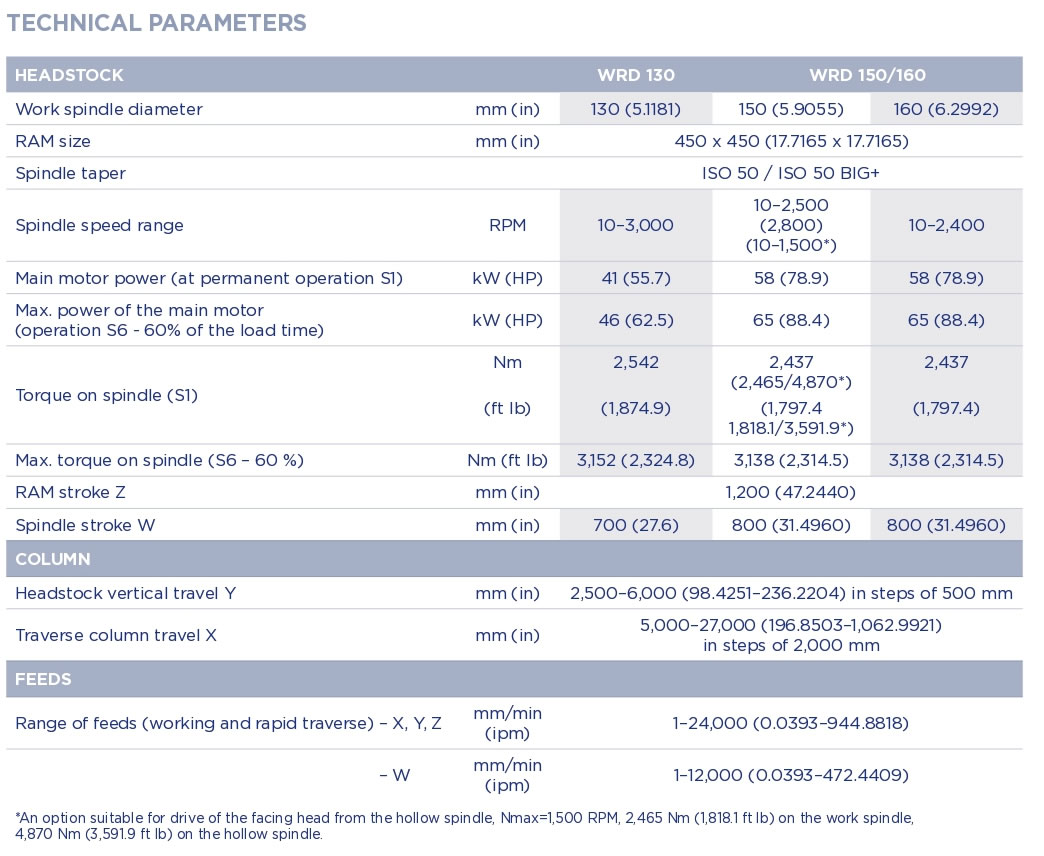

- Work Spindle Diameter: 130mm (5.11") / 150mm (5.9") / 160mm (6.3")

- Spindle Speed Range: WRD 130- 3,000 RPM / WRD 150- 2,500 RPM (Opt. 2,800 & 1,500) / WRD 160- 2,400 RPM

- RAM Size: 450 x 450mm (17.7 x 17.7")

- RAM Stroke Z Travel: 1,20mm (47.2")

- X Travel-Column Traverse: 5,000- 29,000 Plus (196" – 1,141) in 2,000mm increments

- Y Travel-Headstock Vertical Travel: 2,000 – 6,000mm (98" – 236") in increments of 500mm

- W Travel-Spindle Stroke: WRD 130 -700mm (27.6) / WRD 150- 800mm (31.5") / WRD 160-800mm (31.5")

- Optional Accessories: Rotary Tables, Floor Plates, Angle Plates, Clamping Cubes, Milling Heads, Facing Heads, Automatic Tool Changers, Pickup Stations for Automatic Exchange of Special Accessories, Etc.