The horizontal milling and boring machine WHN 13/15 is a universal machine designed for precise milling, line-coordinate drilling, boring and thread cutting of box- and board-type workpieces as well as complicated workpieces from cast-iron, steel cast-iron and steel with the weight of up to 25,000 kg. WHN 13/15 is the most successful machine from the company production. The first model of the machine was produced in 1968. The success of this machine can be documented by the fact that almost 2,800 pieces of these machines have been sold up to now.

It particularly excels in the ratio between capacity and the purchasing costs. The users value the structure of the machine, which guarantees high rigidity and reliability as well as high technical parameters and a broad range and comfort of the technological features. They can be extended with a wide selection of technological accessories that significantly widen the machine technological utility value.

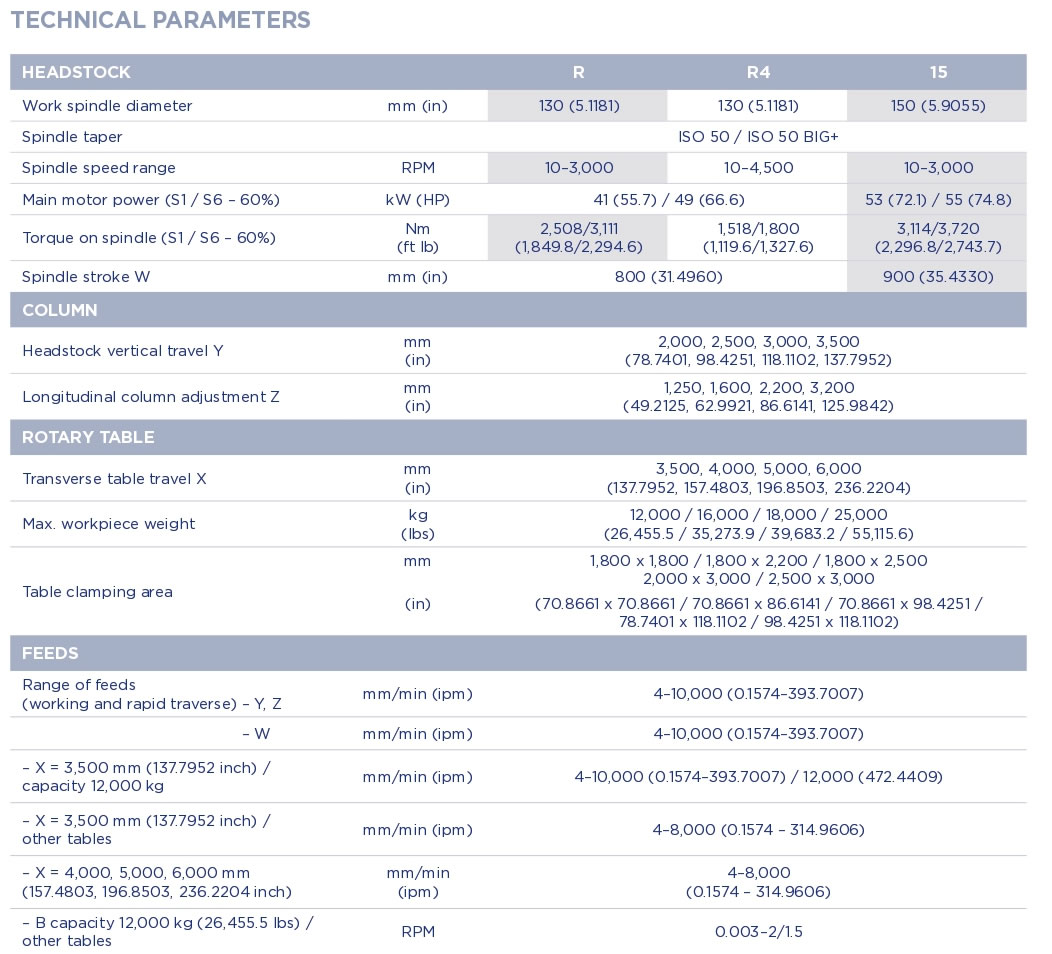

- Work Spindle Diameter: 130mm (5.11") / 150mm (5.9")

- Spindle Speed Range: 10-3,000 RPM / (Optional 10-4,500 RPM on WHN 13)

- X Travel-Table Traverse: 3,500 / 4,000 / 5,000 / 6,000mm (137" / 157" 196" / 236")

- Y Travel-Headstock Vertical Travel: 2,000 / 2,500 / 3,000 / 3,500mm (78" / 98" / 118" / 137")

- Z Travel- Longitudinal Column Travel: 1,250 / 1,600 / 2,200 / 3,200mm (49" / 63" / 86" / 126")

- W Travel-Spindle Stroke: 800mm (31.5") / 900mm (35.4")

- Table Clamping Area: 1,800 x 1,800mm (70" x 70") / 1,800 x 2,220mm (70" x 86") / 1,800 x 2,500mm (70" x 98") / 2,000 x 3,000mm (78" x 118") / 2,500 x 3,000mm (98" x 118")

- Max Workpiece Weight: 12,000kg (26,455 lbs.) / 25,000kg (55,115 lbs.)

- Pallet Changer, Angle Plates, Clamping Cubes, Milling Heads, Facing Heads, Automatic Tool Changers, Pickup Stations for Automatic Exchange of Special Accessories, Etc