Machine frame

Basic heavy machine parts (tables, palletes, longitudinal and transverse beds) are casted from grey iron. The machine column is designed as a twin-shell casting also made of grey iron with an optimised structure. The high rigidity of the whole machine structure is ensured by joining the X and Z axes together.

Balancing

The headstock weight is hydro-mechanically compensated (by a hydraulic cylinder) using a standalone hydraulic unit.

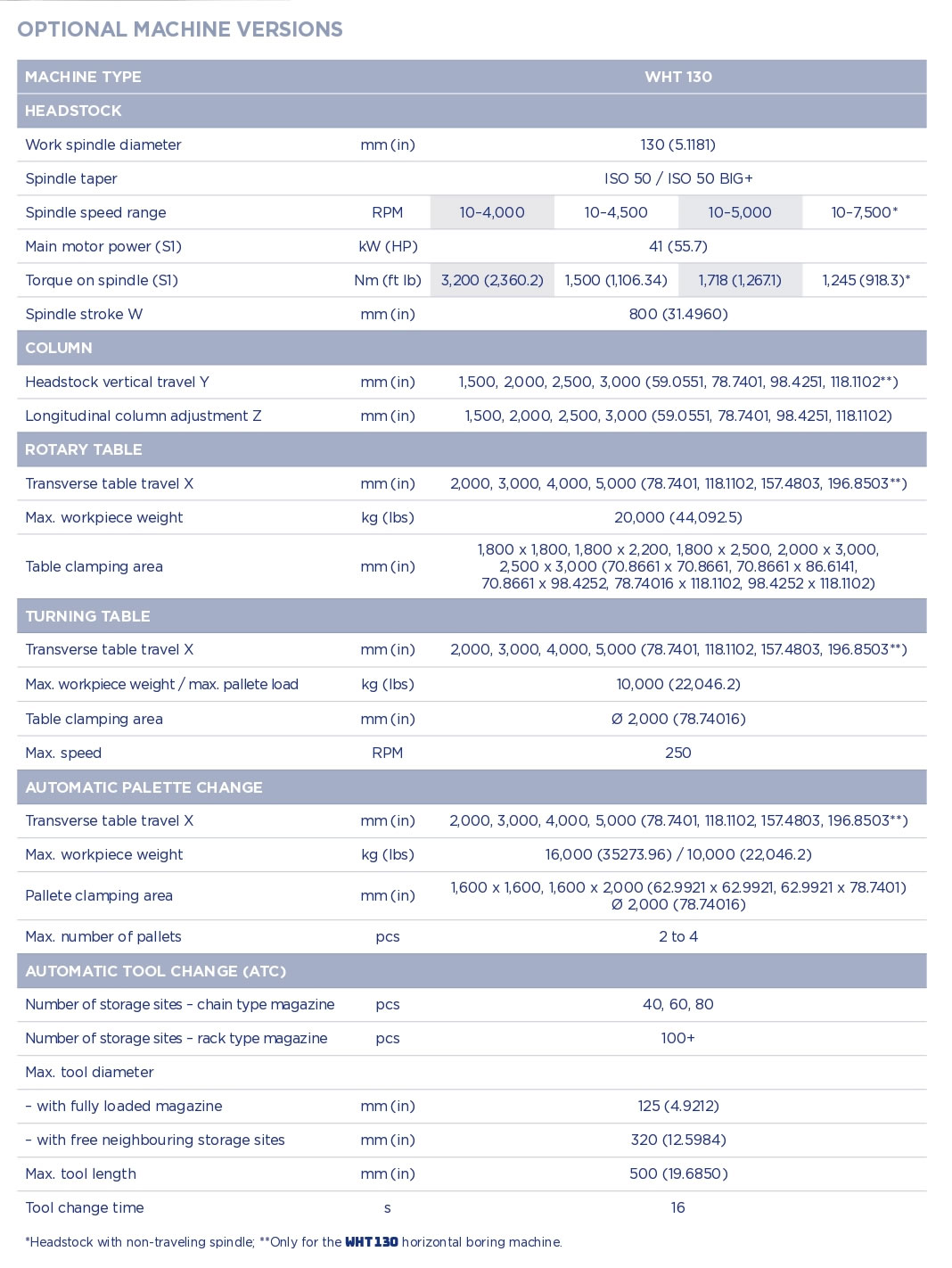

- Work Spindle Diameter: 130 (5.1")

- Spindle Speed Range: 4,000 RPM / 4,500 / 5,000 rpm / 7,500* (no travelling spindle)

- X Travel-Table Traverse: 2,000 / 3,000mm / 4,000 / 5,000 (78" / 118" / 157" / 196")

- Y Travel-Headstock Vertical Travel: 1,500 / 2 ,000 / 2,500mm / 3,000 (59" / 78" / 98" / 118")

- Z Travel- Longitudinal Column Travel: 1,500 / 2 ,000 / 2,500mm / 3,000 (59" / 78" / 98" / 118")

- W Travel-Spindle Stroke: 800mm (31.5")

- Table Clamping Area: 1,800 x 1,800mm (70" x 70") / 1,800 x 2,220mm (70" x 86") / 1,800 x 2,500mm (70" x 98") / 2,000 x 3,000mm (78" x 118") / 2,500 x 3,000mm (98" x 118")

- Max Workpiece Weight: 20,000kg (44,092 lbs.)

- Turning Table: 2,000 Diameter (78")/ Max Weight Capacity 10,000kg(22,046 lbs.) 250 RPM

- Pallet Changer, Angle Plates, Clamping Cubes, Milling Heads, Facing Heads, Automatic Tool Changers, Pickup Stations for Automatic Exchange of Special Accessories, Etc