The horizontal table-type boring machines MAXIMA I/II are another representative of the CNC generation of TOS VARNSDORF machines, which excel in the top level of performance parameters and a user comfort based on technically advanced concept and a broad offer of variants and user functions. The structure of the machine is based on structural groups of the WRD machines, which are arranged in a cross-mounting of the table-type machines. The MAXIMA boring machines are characterized by a modern technical design of the structure and high level of performance. The MAXIMA machines are equipped with a traveling RAM and a work spindle. The machine can be supplemented with a series of technological devices, which greatly extend the machines potentialities.

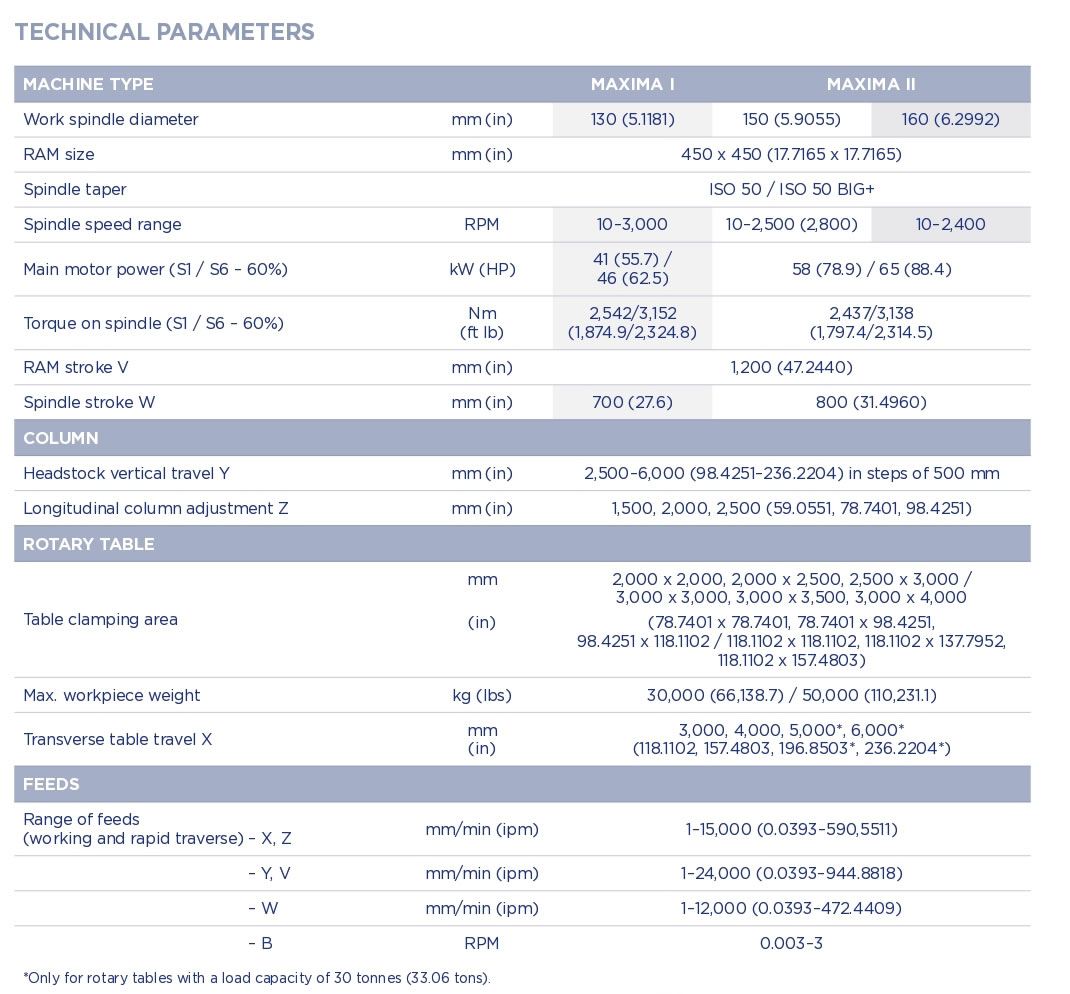

- Work Spindle Diameter: 130mm (5.11") / 150mm (5.9") / 160mm (6.3")

- Spindle Speed Range: 10-3,000 RPM / 10-2,500 RPM(opt. 2,800) / 10-2,400 RPM

- RAM Size: 450 x 450mm (17.7 x 17.7")

- RAM Stroke V Travel: 1,200mm (47.2")

- X Travel-Table Traverse: 3,500 / 4,000 / 5,000 / 6,000mm* (137" / 157" 196" / 236")

- Y Travel-Headstock Vertical Travel: 2,000 – 6,000mm (98" – 236") in increments of 500mm

- Z Travel- Longitudinal Column Travel: 1,500 / 2,000 / 2,500mm (59" / 78" / 98")

- W Travel-Spindle Stroke: 700mm (27.6") / 800mm (31.5")

- Table Clamping Area: 2,000 x 2,000mm (78" x 78") / 2,500 x 2,500mm (78" x 98") / 3,000 x 3,000mm (118" x 118") / 3,000 x 3,500mm (118" x 137") / 3,000 x 4,000mm (118" x 157")

- Max Workpiece Weight: 30,000kg (66,138 lbs.) / 50,000kg (110,231 lbs.)

- Pallet Changer, Angle Plates, Clamping Cubes, Milling Heads, Facing Heads, Automatic Tool Changers, Pickup Stations for Automatic Exchange of Special Accessories, Etc