The horizontal milling and boring machine WH 105 is a modern, efficient, continuously controlled milling machine. The high cutting parameters and broad comfort of technological features predestine this machine for application in very demanding technological operations. The continuous control of the X, Y, Z and W coordinates and the rotating positioning table create conditions for universal application. It can be used for efficient milling of box-type components from multiple sizes as well as milling of moulds and other complicated workpieces.

The machine can be supplemented with a series of technological devices, which greatly extend technological possibilities.

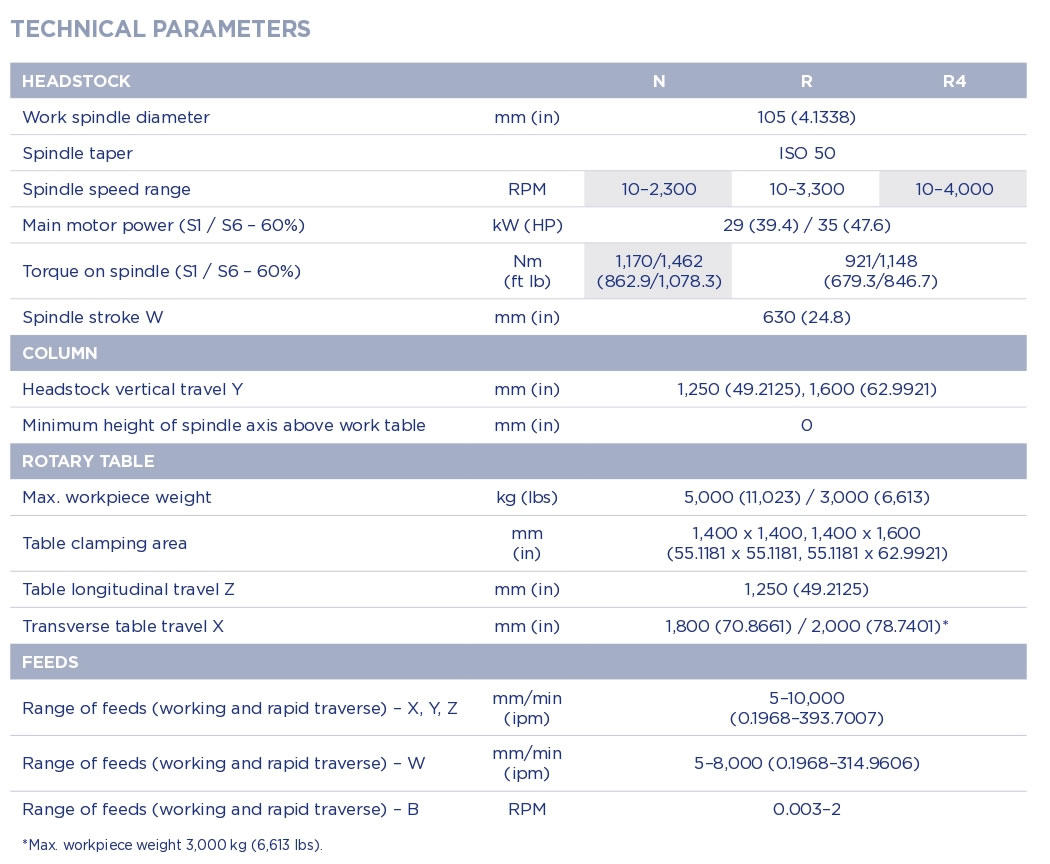

- Work Spindle Diameter: 105mm (4.13")

- X Travel-Table Traverse: 1,800/2,000mm (70" / 78")

- Y Travel-Headstock Vertical Travel: 1,250mm/1,600mm (49"/63")

- Z Travel- Longitudinal Table Travel: 1,250mm (49")

- W Travel-Spindle Stroke: 630mm (24.8")

- Table Clamping Area: 1,400 x 1,400mm (55" x 55")/ 1,400x1,600mm (55" x 63")

- Max Workpiece Weight: 5,000/3,000kg (11,023/6,613 lbs.)

- Angle Plates, Clamping Cubes, Milling Heads, Facing Heads, Automatic Tool Changers, Pickup Stations for Automatic Exchange of Special Accessories, Etc